” Double mitre saw production line DAS-FL

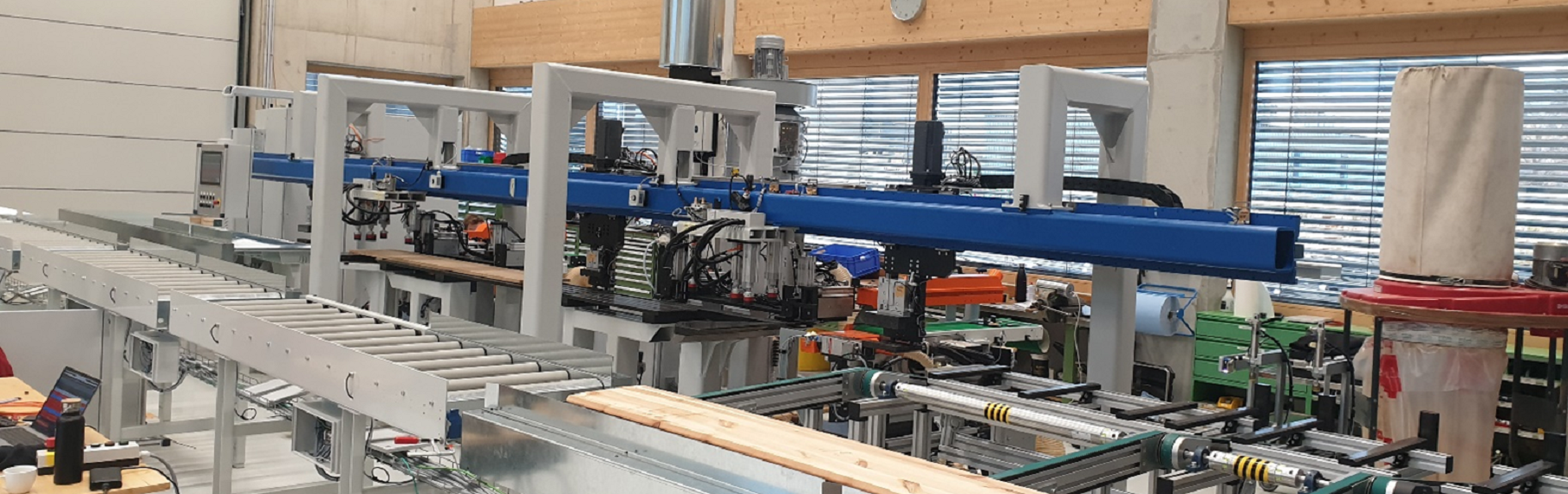

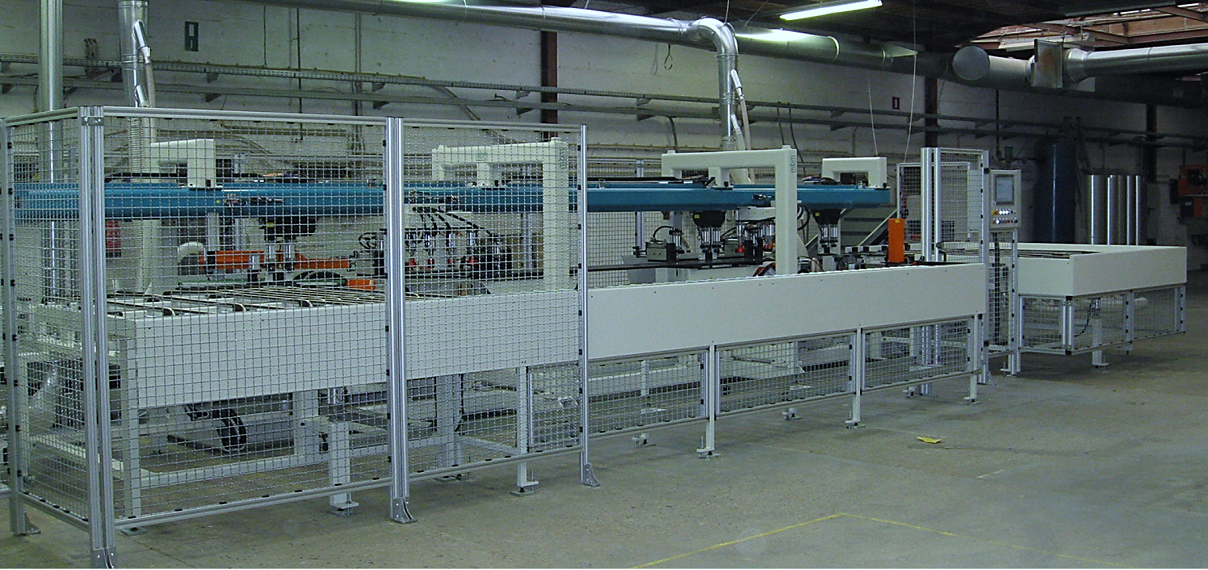

The DAS-FL production line is an automated solution that has been specially designed for the industrial production of coffin parts. It guarantees the gap-free production of coffin parts with precisely fitting mitre angles without the need for reworking.

- Efficient, automatic operation: Complete automation leads to more efficient work processes in coffin production

- Dimensionally and angularly accurate cuts: Precise cuts in terms of dimensions and angles

- Perfect cut quality: high-quality cuts without defects

- Scratch and trace-free surface: the surfaces remain undamaged

- Precision for life: long-term accuracy and reliability

- Shorter machine downtimes: Less time lost due to ancillary work such as regrinding

- Flexibility: products can be changed over immediately, which increases adaptability

- The DAS-FL is suitable for trapezoidal and normal coffin shapes, for example:

- House roof mould, body mould coffin, German, Swiss, Italian, French and Scandinavian coffin moulds as well as the American chest coffin and for bone chests

- Two sawing units produce precise mitre cuts for coffin parts such as side panels, head section, foot section, lid and base in a single pass

- The DAS-FL delivers high cutting quality by firmly fixing the parts by pressing them onto the support surface during cutting

- Precise mitre cuts with straight joint and with milled groove

- An integrated grooving unit creates a groove for joint nails that matches the board thickness

- Suitable for all types of wood, whether raw, coated or veneered. For example: Spruce, fir, pine, oak, larch, MDF, multi-layer or chipboard

- DAS-FL basic machine

- as a production line with two double mitre saws

- DAS-FLT for sawing with T-strips already applied

- Adapted gripping technology with a corresponding recess for T-bar

- Customised clamping technology prepared for T-bar

- Customised sawing unit prepared for T-bar

- Customised grooving unit for T-bar

- DAS-FL with grooving unit for straight groove

- The version with grooving unit for dovetail joints (anime) is available as an option

- DAS-FL with product data tracking

- For continuous product data tracking, order data or order-related parameters such as quality, material and lengths can be transferred from the product to the system

- The system can be operated both as a stand-alone solution and inline, thus enabling integration into existing production lines

- The DAS-FL production line can be combined with other machines.

- Automatic moulding assembly machine

- Drilling stations for precise handle drillings or lock drillings

- Conveyor technology such as return roller conveyors, cross conveyors or waste removal conveyors

- Board magazine, for the storage of blanks

- Panel types (raw part)

- All types of wood, whether raw, coated or veneered. For example: Spruce, fir, pine, oak, larch, MDF, multilayer or chipboard

- Blank panel length: 1,500 mm – 2,200 mm

- Blank panel width: 200 mm – 660 mm

- Workpiece sizes (parts cut)

- Part length cut: 300 mm – 2,180 mm

- Part length with two simultaneous cuts: maximum 2,170 mm

- Part width at 90°: 200 mm – 660 mm

- Part width at 45°: 200 mm – 460 mm

- Cutting height

- Saw blade Ø 350 mm: at 90°: max. 60 mm at 45°: max. 40 mm

- Saw blade Ø 400 mm at 90°: max. 85 mm at 45°: max. 55 mm

- Mitre angle

- Saw unit carriage (large mitre): 90° – 45°

- Saw blade (small mitre): 90° – 45°

- Slotting unit

- Diameter Ø 180 mm

- Inner diameter Ø 30 mm

- Feed rate

- Sawing unit before: 1 – 30 m/min

- Sawing unit back: 1 – 30 m/min

- Note: Data may vary for different types of wood and dimensions

- Cycle time

- From min. 14 to max. 20 sec. per part depending on the finishing variant (grooving, drilling, etc.)

- Note: Data may vary for different types of wood and dimensions

- Siemens as the leading brand for electrical and electronic components with a TIA-PLC central control system (safe version) for system, sequence and safety control

- Master computer for article and product management, product tracking, parameter management, manual operation, alarm management, data recording

- Touchscreen HMI control panel

- Simple programme creation with coffin configurator

- Large storage capacity for customised editing programmes

- Automatic angle and length adjustment

- Fault diagnosis for malfunctions

- Correction of the length and groove height for different wood thicknesses

- Cutting different programmes from one piece of wood

- Control options

- Interface for automatic transfer of production data

- Remote diagnostics and remote maintenance solutions

IoT platform control: For monitoring and production data acquisition and networking with upstream or downstream systems. Further information at: control- digifai.

- Sturdy welded design

- Length: approx. 9,760 mm with add-on modules up to 14,000 mm (basic machine without safety fence)

- Width: approx. 2,106 mm with add-on modules up to 4,600 mm (basic machine without safety fence)

- Height: approx. 2,284 mm

- Weight DAS-FL

- 8,200 kg (basic machine)

- Connected load: approx. 39 kW

- Mains voltage 400 V / 50 Hz

- Compressed air requirement: approx. 3,000 l/min. at the maintenance unit

- Operating pressure: min. 6 bar overpressure

- Extraction volume: approx. 5,600 m³/h at 32 m/s air speed

- Ambient temperature of the machine: in the range from + 10°C to + 40°C