- Attachable to the DAS-FL: Add an automatic drilling station to the DAS-FL

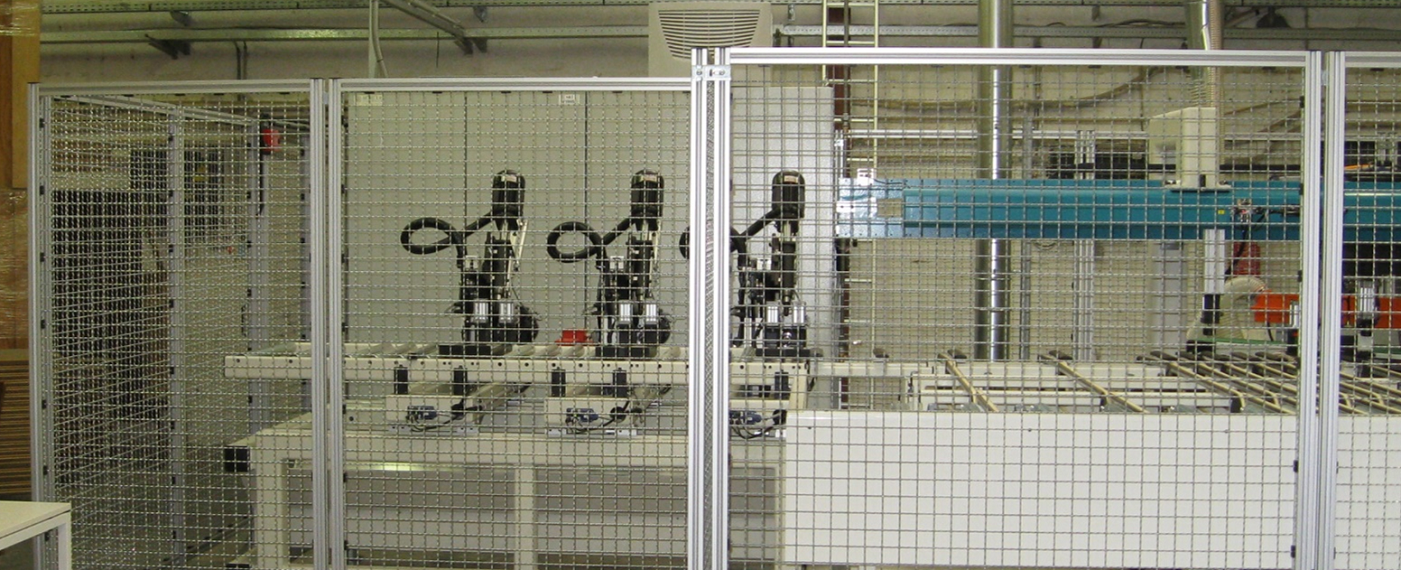

- Increased productivity: Automatic drilling stations can work continuously, without breaks, which significantly increases the production rate

- Precision and repeatability: These machines offer high accuracy and consistency in every drilling operation, which improves the quality of the end products

- Cost efficiency: Automation reduces labour costs and increases efficiency as less manual intervention is required

- Flexibility: Automatic drilling stations can be easily adapted to different drilling requirements, including the processing of different materials and geometries

- Safety: Automated drilling stations reduce the risk of industrial accidents as less human intervention is required

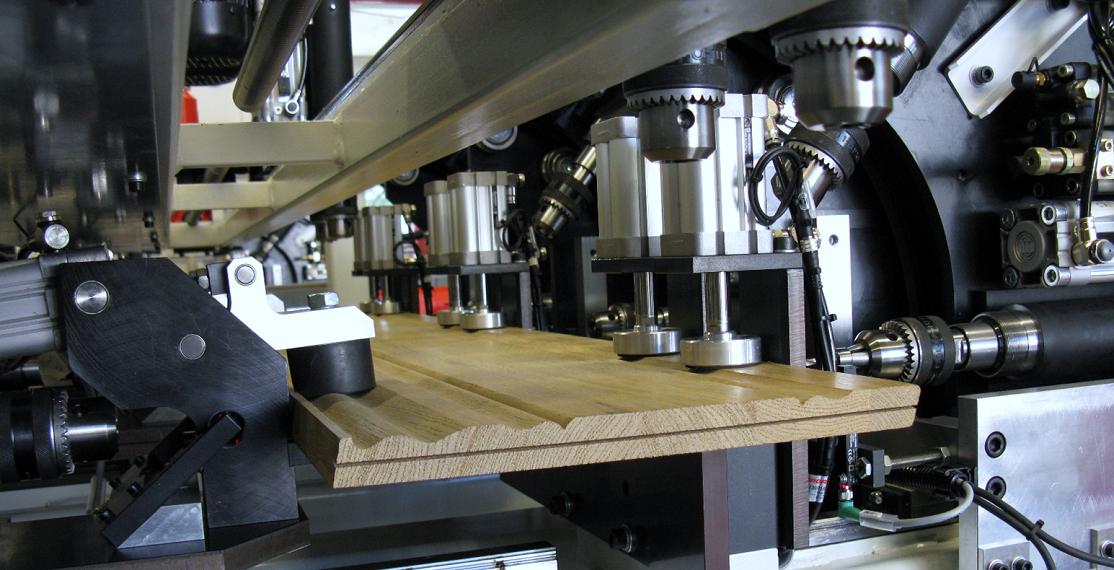

- Electrically adjustable single drilling units for the fixing holes

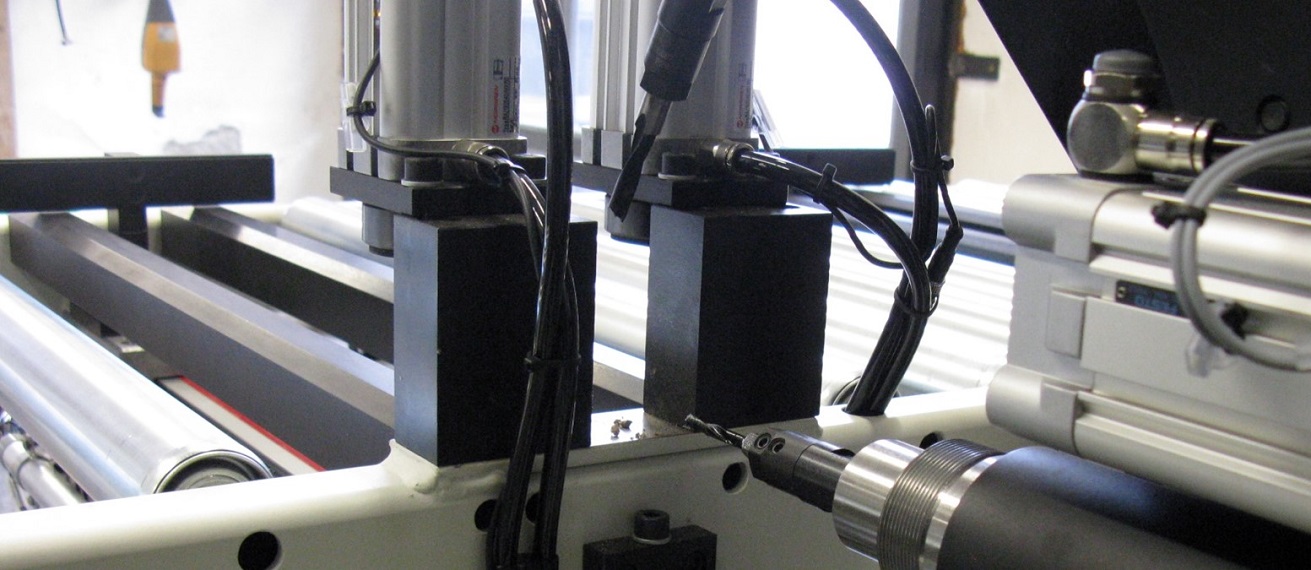

- Linear travel axes for X, Y, Z direction

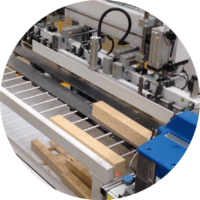

- Fixing the workpieces with clamping cylinders

- Cycle time designed for DAS-FL cycle and simultaneous drilling of up to 6 holes

- Drill stroke = 80 mm, with reducing chuck for drill shank diameter 10 mm.

- Siemens as the leading brand for electrical and electronic components with a TIA-PLC central control system (safe version) for system, sequence and safety control

- Parameter management, manual mode, alarm management, data recording

- Touchscreen HMI control panel

- Simple programme creation with coffin configurator

- Fault diagnosis for malfunctions

- Correction of the length and groove height for different wood thicknesses

- Cutting different programmes from one piece of wood

- Control options

- Interface for automatic transfer of production data

- Remote diagnostics and remote maintenance solutions

- IoT platform control: For monitoring and production data acquisition and networking with upstream or downstream systems. Further information at: control – digifai